```html

What Is Differential Fluid and Why Does It Matter?

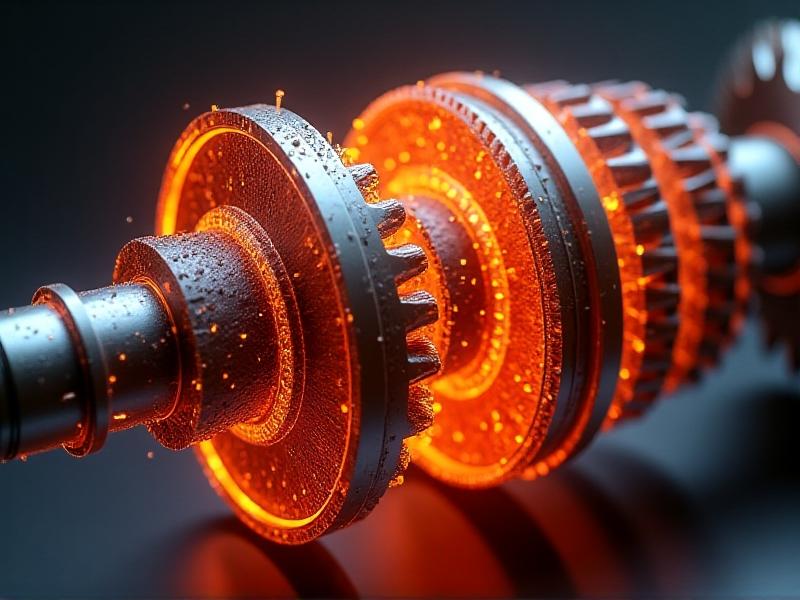

Differential fluid, often called gear oil, is a specialized lubricant designed to protect the gears, bearings, and other components inside a vehicle's differential. This unassuming fluid plays a critical role in managing heat, reducing friction, and preventing metal-on-metal wear as power transfers from the driveshaft to the wheels. Unlike engine oil, differential fluid is formulated to withstand extreme pressure, ensuring smooth operation even under heavy loads or sharp turns. Despite its importance, many drivers overlook it entirely, assuming transmissions or engines are the sole focus of maintenance.

Modern differentials operate in harsh environments. During cornering, the wheels rotate at different speeds, creating intense stress within the differential. Without proper lubrication, gears can overheat, leading to premature failure. Vehicles with limited-slip or locking differentials rely on additives in the fluid to maintain clutch plate functionality. Over time, heat and contamination break down the fluid’s viscosity and protective additives, leaving components vulnerable. Yet, because differentials are sealed and out of sight, their maintenance often falls by the wayside until a costly repair looms.

The Hidden Role of Differentials in Your Vehicle

Differentials are mechanical marvels that allow wheels to rotate independently while delivering power evenly. In rear-wheel-drive vehicles, the differential sits between the rear wheels; all-wheel-drive systems have front and rear differentials, plus a transfer case. Off-road trucks and performance cars often feature reinforced or locking differentials to optimize traction. Each design depends on clean, effective fluid to function. When fluid degrades, the differential can’t dissipate heat efficiently, leading to warped gears or bearing seizures.

Consider a pickup truck towing a trailer uphill: the differential works overtime to distribute torque. If the fluid is old or low, friction spikes, creating metal shavings that circulate like sandpaper. This accelerates wear and can trigger a chain reaction of damage across the drivetrain. Even in daily driving, stop-and-go traffic places repeated stress on differential components. Regular fluid changes are a small investment compared to rebuilding an entire axle assembly.

Types of Differentials and Their Fluid Needs

Not all differentials are created equal, and neither are their fluid requirements.

Open differentials

, common in most passenger cars, use standard gear oil.

Limited-slip differentials (LSD)

, found in performance vehicles, require fluid with friction modifiers to prevent clutch chatter.

Locking differentials

, popular in off-road rigs, need robust lubricants that can handle sudden torque shifts. Hybrid and electric vehicles often employ specialized e-differentials with unique thermal management needs.

Using the wrong fluid can be disastrous. For instance, LSDs without proper additives may shudder during turns, while conventional gear oil lacks the shear stability for high-torque applications. Always consult your owner’s manual or a trusted mechanic to match the fluid to your differential’s design. Some manufacturers even specify synthetic blends for extended drain intervals or extreme temperatures.

Silent Symptoms: How to Spot Failing Differential Fluid

Differential problems rarely announce themselves dramatically. Early warning signs are subtle: a faint whining noise during acceleration, a slight vibration at highway speeds, or a sluggish feel when cornering. These symptoms often mimic other issues, leading misdiagnoses. For example, a humming sound might be mistaken for wheel bearing failure. However, if the noise changes pitch when turning left or right, the differential is likely the culprit.

Inspect for leaks around the differential cover or axle seals. Dark, gritty fluid on the dipstick (if equipped) indicates contamination. Some modern vehicles omit dipsticks, making visual checks impossible without removing the fill plug. If you notice a burnt smell after driving or spot puddles of thick oil under the axle, schedule a service immediately. Ignoring these signs can lead to catastrophic failure, stranding you on the roadside.

How Often Should You Change Differential Fluid?

Manufacturer recommendations vary widely. Some suggest every 30,000 miles, while others claim lifetime fill intervals. However, “lifetime” typically means the vehicle’s warranty period—not your ownership. Severe driving conditions—towing, off-roading, or frequent short trips—demand more frequent changes. As a rule of thumb, inspect the fluid annually and replace it every 50,000 miles for average use.

Newer synthetic fluids boast longer service lives but still degrade over time. A used fluid analysis can reveal its condition, but for most drivers, sticking to a proactive schedule is simpler. Note that front and rear differentials may have different service intervals, especially in 4x4s. Always address leaks promptly, as low fluid levels cause immediate damage.

DIY Differential Service: A Step-by-Step Guide

Changing differential fluid is manageable for DIYers with basic tools. Start by gathering gear oil, a pump, a socket set, and a new gasket or RTV sealant. Safely elevate the vehicle and locate the differential’s fill and drain plugs. Remove the fill plug first (to avoid a vacuum lock), then drain the old fluid. Inspect the drain plug for metal particles—a few specks are normal; chunks signal trouble.

Clean the housing mating surface, apply a new gasket, and refill with fresh fluid until it dribbles from the fill hole. Use a pump for precision, as overfilling can cause leaks. Torque the plugs to spec and take a test drive. Listen for changes in noise and check for leaks. While straightforward, this job can get messy, so wear gloves and lay down cardboard.

The Cost of Ignoring Your Differential

Neglected differentials often fail spectacularly. Worn bearings can seize, locking the rear wheels at speed. Metal shavings circulate, scoring gear teeth and ruining the housing. A full rebuild can cost $1,500–$3,000, depending on the vehicle. For luxury cars or heavy-duty trucks, expenses climb higher. Compare this to a $100–$300 fluid service, and the math is clear: prevention trumps repair.

Resale value also suffers. A neglected differential hints at broader maintenance apathy, deterring savvy buyers. Conversely, a service record showing regular fluid changes boosts confidence and resale price. Think of differential service not as an expense, but as insurance for your drivetrain’s longevity.

Choosing the Right Fluid for Your Vehicle

Selecting gear oil involves matching viscosity and specifications to your differential. Most modern vehicles use 75W-90 or 80W-90 grades, but check your manual. API GL-5 is standard for hypoid gears, while GL-4 suits older transmissions. Synthetic oils excel in extreme temperatures and last longer. For limited-slip units, ensure the fluid contains friction modifiers—look for labels like “LS” or “Limited Slip.”

Brand matters less than certification. Stick with reputable manufacturers that meet OEM specs. When in doubt, consult forums specific to your vehicle. Enthusiast communities often share tested fluid recommendations for particular driving styles or climates.

Professional vs. Home Service: What’s Best?

DIY fluid changes save money but require time, tools, and disposal of hazardous waste. Professionals offer speed, expertise, and disposal compliance. They’ll also spot issues like worn seals or bearings during the service. For complex systems—like AWD vehicles with multiple differentials—a shop’s lift and specialized tools justify the cost.

If you’re uncomfortable working under a vehicle or lack tools, professional service is wise. However, for enthusiasts, DIY provides satisfaction and deeper mechanical understanding. Either way, prioritize quality fluids and proper procedures.

Integrating Differential Care into Your Routine

Add differential checks to your seasonal maintenance ritual. When rotating tires, glance for leaks or crusty residue around the axle. Note fluid changes in your logbook or app. If you off-road or tow, shorten intervals by 20–30%. Teach new drivers in your household about the differential’s role—awareness prevents oversight.

Finally, advocate for transparency. Ask your mechanic to include differential inspections in multipoint checks. By treating differential fluid as essential as engine oil, you’ll safeguard your vehicle’s hidden hero and enjoy smoother, safer drives for years.